As Industry 4.0 accelerates smart manufacturing and automation, industrial Panel PCs with advanced touch screen technology are the heart of modern human-machine interfaces (HMI). Selecting the right touch solution is not only about user experience, but also long-term reliability, hygiene, and safety—even in harsh environments. This article examines the technical foundations of major touch technologies, multi-touch operation, mechanical durability, and the core considerations that guide successful deployment of industrial touch Panel PCs.

Touchscreen Technologies: An Industrial Perspective

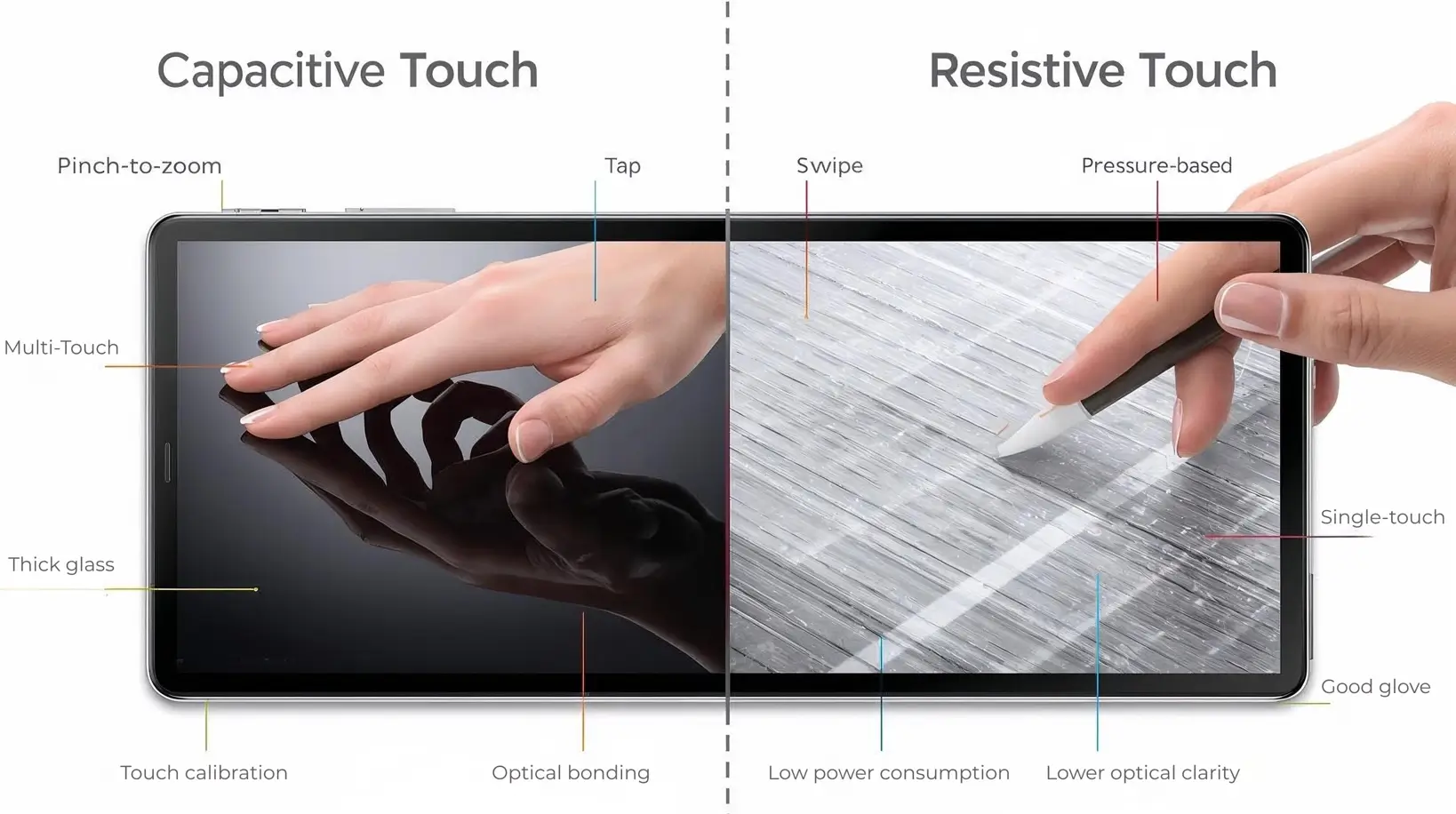

Capacitive Touch Technology

Capacitive touch screens operate based on the electrical properties of the human body, allowing seamless interaction by detecting changes in the electrostatic field. These screens typically use a transparent electrode layer, placed on the glass surface. When a finger (or a conductive stylus) touches the screen, it alters the local electrostatic field, enabling the detection and localization of the touch point.

Key advantages:

- Supports multi-touch (up to 10 fingers simultaneously)

- High optical clarity and responsive accuracy

- Ideal for quick, complex gestures (zooming, scrolling, etc.)

Considerations:

- Requires bare fingers or capacitive gloves

- Sensitive to liquid interference if inadequately protected

Resistive Touch Technology

Resistive touch screens detect input based on physical pressure. The structure comprises two thin, flexible layers separated by a fine gap. When a finger, pen, or gloved hand presses on the surface, the two layers make contact, and the resulting voltage change determines the position of the touch.

Distinct features:

- Works with any input (gloves, stylus, even tools)

- Superior tolerance against dust and moisture

- Slightly lower clarity and single-point input only

Typical use cases: environments where gloves or rugged operation are common, such as factories with heavy contamination or temperature extremes.

Other Industrial Touch Technologies

For specific industrial circumstances, additional technologies are available.

Infrared (IR):

- Utilizes grids of invisible infrared light beams across the panel

- Touch is detected by interruption of light beams

- No overlay on the screen, excellent clarity and durability

- Susceptible to high dust and direct sunlight interference

Surface Acoustic Wave (SAW):

- Uses ultrasonic waves across the glass surface

- Highly sensitive, but not suitable for locations with excessive dust or water

Multi-Touch Operation: Principles and Value

How Multi-Touch Works

Multi-touch technology, especially using capacitive touch panels, enables the PC to sense and interpret multiple simultaneous touch points. This is typically achieved by arraying intersections of capacitive grids across the display. Each intersection tracks changes independently, allowing complex gestures and concurrent user input.

Value for Industrial Applications

- Enhanced Efficiency: Multi-touch optimizes user control, allowing multitasking such as adjusting machine parameters or manipulating graphical objects in HMIs.

- Advanced Visualization: Enables pinch-to-zoom and rotation, critical for navigating complex schematics and diagnostics.

- Improved User Experience: Natural gestures reduce training time and errors, especially for staff familiar with consumer devices.

Deployment Considerations

Industrial environments require multi-touch panels with advanced signal processing to avoid false touches due to water droplets, electromagnetic interference, or concurrent gloves.

Built for Endurance: Waterproof and Dustproof Design

IP Ratings and Their Meaning

The Ingress Protection (IP) rating is the industry benchmark for waterproof and dustproof reliability. For example, an IP65-rated panel is fully dust-tight and can withstand low-pressure water jets from any direction.

Industrial Mechanisms for Ruggedness

- Sealed Front Bezel: Frame and display are tightly joined, often using gaskets, to prevent intrusion of water and dirt.

- Protected Connectors: Rear and side ports feature covers, rubber seals, and corrosion-resistant metals.

- Materials Selection: Front panels use industrial-grade, chemically reinforced, often anti-corrosive glass.

Escenarios de aplicación

High IP-rated Panel PCs excel in:

- Food and beverage factories (regular washdowns)

- Outdoor control systems (rain, sand, UV exposure)

- Chemical plants (corrosives, fine powders)

Underlying Technical Aspects

Panel Construction and Signal Processing

- Material Selection: Touch panels use multi-layered glass and conductive coatings (such as ITO), balancing sensitivity with impact resistance.

- Controller Algorithms: Modern touch controllers analyze minute variations in capacitance or resistance, using filters to differentiate intentional touches from noise.

- Calibration: Regular or automatic calibration may be needed in changing environmental conditions.

Embedded System Integration

- Touch modules are directly integrated with embedded industrial PCs, ensuring regulatory compliance, EMI shielding, and robust OS support, from Windows IoT to custom Linux builds.

- Additional features: glove mode, water rejection, sunlight-readable displays.

Technical Comparison and Selection Guide

How to Choose the Right Touch Technology

| Tecnología | Input Types | Multi-touch | Ruggedness | Clarity | Best for |

|---|---|---|---|---|---|

| Capacitivo | Finger, capacitive pen | Yes (up to 10) | Moderate-High | Alta | Clean, precise applications (labs, medical, HMI) |

| Resistivo | Finger, glove, stylus, tools | No | Alta | Fair | Dirty, industrial, gloved operation |

| Infrared | Any solid object | Sí | Moderado | Very High | Kiosks, ticketing, light-controlled spaces |

| SAW | Finger | Sí | Moderado | Highest | High clarity needed, low contamination |

- Operating environment (contaminants, gloves, outdoor)

- Required gestures and multitasking

- Maintenance and cleaning procedures

- Desired IP ratings and protection levels

Case Example

A food-processing facility with frequent washdowns should choose an IP66 capacitive or infrared system for best reliability and hygiene. Conversely, a dusty steel fabrication shop may favor resistive touch to minimize false inputs.

Preguntas más frecuentes (FAQ)

How do you maintain durability and touch accuracy over time?

Industrial touch panels are engineered for millions of activation cycles, reinforced front glass, and sealed construction. Regular cleaning with non-abrasive agents, occasional recalibration, and routine dust removal from connectors extend operational lifespan.

What should I do if my Panel PC touch screen does not register input?

Check for excessive dirt, water droplets, or damage. For capacitive panels, ensure no strong EMI sources are nearby. For resistive screens, inspect for surface wear or delamination.

Can industrial touch panels function with gloves?

Yes, but the success depends on the technology:

- Resistive: Always works with gloves.

- Capacitive: Needs capacitive or thin gloves, though modern industrial models support glove operation modes.

Beyond Info System: Company Profile & Product Overview

Acerca de Beyond Info System

Beyond Info System Co., Ltd. (www.beyondinfosys.com) is a Taiwan-based leader in industrial Panel PC manufacturing, specializing in rugged, high-performance touch solutions for automation, transportation, healthcare, and more. With decades of experience integrating industrial-grade hardware and custom firmware, Beyond Info System delivers reliable HMIs for the world’s most demanding workspaces.

Flagship Touch Panel PC Products

- Industrial Capacitive Panel PCs: IP65/IP66-rated, available in multiple sizes (7”–21”), supporting multi-touch and glove mode.

- Resistive Touch Panel PCs: For harsh ambient environments, highly tolerant of dust and gloves.

- Custom Embedded Solutions: Integrated box PCs, legacy port support, sunlight-readable displays.

Additional Solutions

Beyond Info System also offers rugged touch monitors, fully integrated embedded box PCs, and system design consulting services for industry-specific needs. Explore the full portfolio at www.beyondinfosys.com.