Analyzing the Core Advantages of Embedded PCs: High Performance in Compact Spaces

In the era of Industrial 4.0, the demand for “intelligence at the edge” has forced a radical redesign of industrial computing hardware. System integrators and automation engineers are no longer just looking for raw power; they are seeking the perfect balance between minimal physical footprint and maximum processing capability.

This article explores why the Industrial PC Box (Embedded PC) has become the backbone of modern industrial infrastructure and how it maintains high performance within the tightest constraints.

What is an Embedded PC? Breaking the Conflict Between Size and Power

In traditional computing, “performance” was often synonymous with “size.” Large towers were necessary to house cooling fans, multiple expansion cards, and bulky power supplies. However, in a smart factory or a medical device, space is the most expensive commodity.

Defining the Embedded PC and Its Design Philosophy

An Embedded PC—often referred to as an Industrial PC Box or Embedded Box PC—is a computing platform purposefully built to perform dedicated functions within a larger mechanical or electrical system. Unlike a consumer-grade desktop designed for general multitasking, an embedded PC is “stripped for battle.”

The design philosophy focuses on Integration. By soldering the CPU directly to the motherboard (SoC design) and utilizing high-density circuit layouts, manufacturers can eliminate the need for bulky sockets and cables. This results in a rugged, monolithic block of computing power that can be tucked away into environments where a standard PC would fail within hours.

The Micro-Trend in the Industrial 4.0 Era (Compact Form Factor)

As we move toward “Lightweight Automation,” the physical size of the hardware determines the flexibility of the entire system.

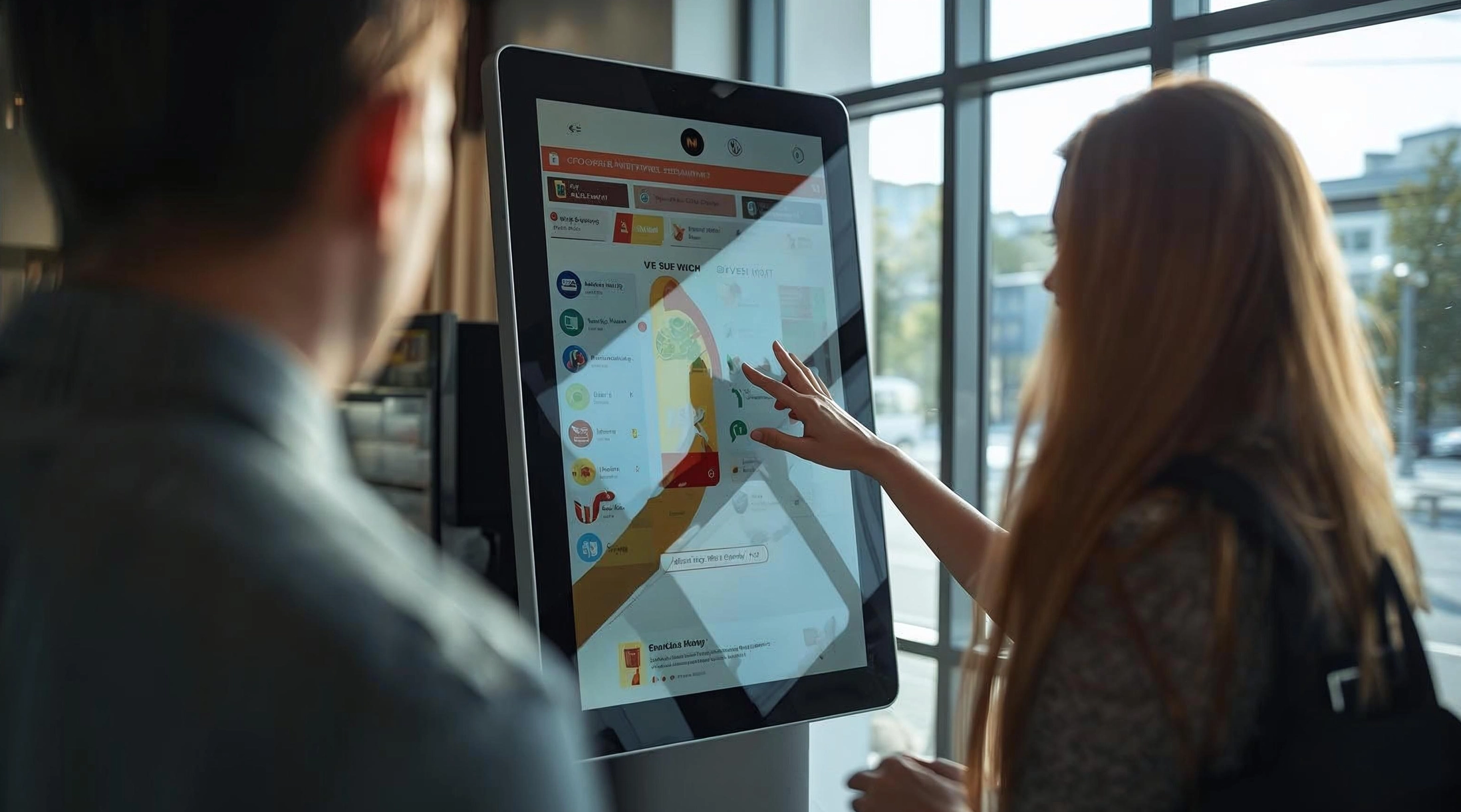

- Space Optimization: Minimal footprints allow engineers to mount PCs directly onto robotic arms, inside thin-profile kiosks, or within crowded electrical cabinets.

- Reduced Total Cost of Ownership (TCO): Smaller units require less specialized mounting hardware and consume less power, leading to long-term savings in energy and maintenance.

| Feature | Embedded PC (Industrial Box PC) | Standard Commercial PC |

| Form Factor | Ultra-Compact / Palm-sized | Tower / Small Form Factor (SFF) |

| Cooling | Fanless / Passive Heat Dissipation | Active Fan Cooling (High Failure Rate) |

| Mounting | DIN-rail, Wall Mount, VESA | Desktop / Floor Standing |

| Lifecycle | 5 – 15 Years (Long-term Support) | 1 – 2 Years (Frequent EOL) |

Fanless Design: The Key Technology for Compact Efficiency

One of the biggest hurdles in miniaturization is heat. In a small, enclosed space, heat is the enemy of electronic longevity. The Fanless Design is the revolutionary answer that allows Embedded PCs to thrive where others melt.

How Passive Cooling Technology Works

Instead of using a mechanical fan to push air across components, a fanless Industrial PC Box uses its own chassis as a massive radiator.

- Heat Pipe Integration: High-performance copper heat pipes sit directly atop the CPU, pulling thermal energy toward the outer shell.

- Extruded Aluminum Fins: The exterior of the PC is typically made of heavy-duty aluminum with deep fins to increase surface area, allowing heat to dissipate naturally through convection.

The Hidden Benefits: Dust Protection and Vibration Resistance

The removal of the fan is not just about noise; it’s about sealing the system.

- Ingress Protection: With no air vents, the PC becomes a “closed-loop” system. Dust, metallic shavings, and moisture—common in factory floors—cannot enter the chassis to cause short circuits.

- Anti-Vibration (Rugged Design): Fans are “moving parts” prone to mechanical failure under vibration. A fanless PC, combined with Industrial SSDs, has zero moving parts, making it compliant with MIL-STD-810G standards for shock and vibration resistance.

High-Performance Computing: An Industrial Heart in a Tiny Body

A common misconception is that “small” means “weak.” Modern silicon technology has allowed Embedded PCs to rival and even surpass mid-range servers in specific tasks.

Top-Tier Processor Support: From Intel Atom to Core i9

Modern Embedded Box PCs utilize specialized “Embedded” variants of processors.

- Efficiency vs. Power: These CPUs (such as the Intel® Core™ i-series T or TE suffixes) are optimized for a specific Thermal Design Power (TDP). They deliver high clock speeds while generating significantly less heat than their desktop counterparts.

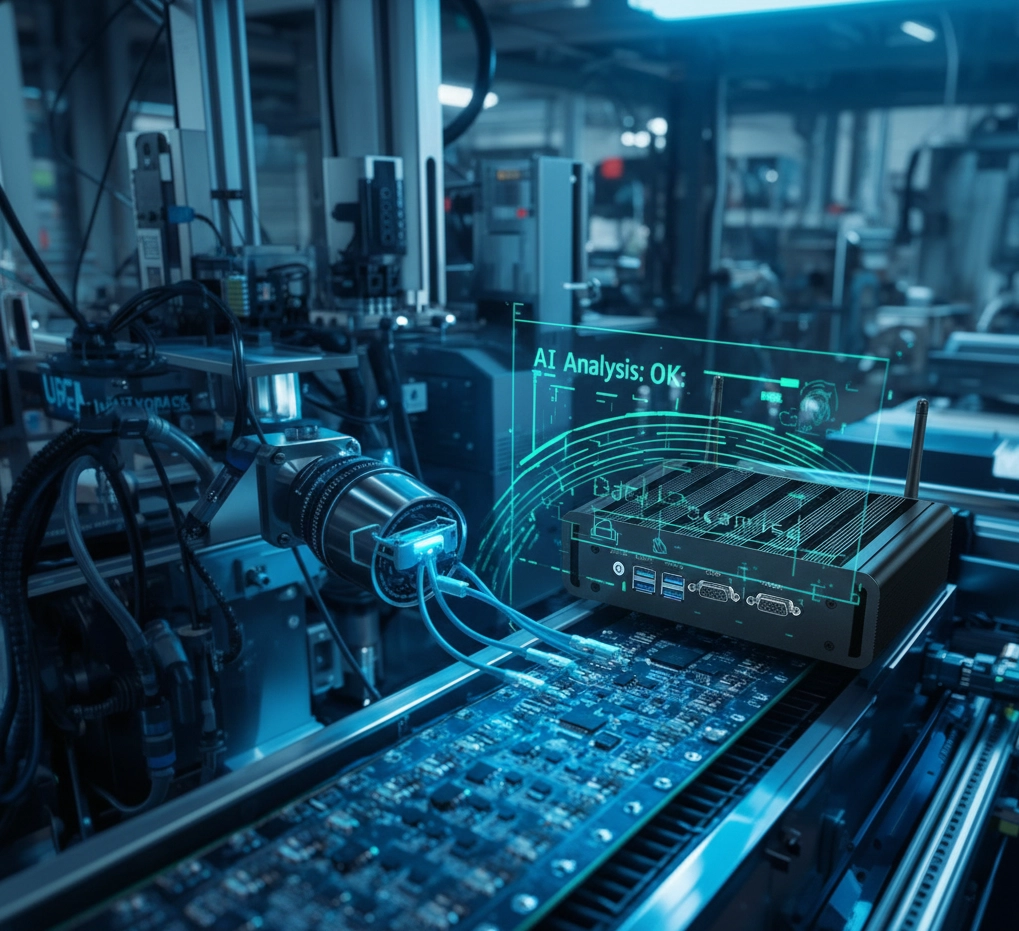

- Edge AI Readiness: Many compact units now integrate NPU (Neural Processing Units) or support high-end mobile GPUs, allowing them to perform real-time AI inference for facial recognition or quality inspection on the fly.

High-Speed Memory and Storage (DDR5 & NVMe SSD)

To prevent data bottlenecks, these compact systems utilize:

- SO-DIMM DDR5: Providing massive bandwidth for multitasking in a fraction of the space.

- M.2 NVMe Storage: Traditional 2.5-inch SATA drives are being replaced by M.2 NVMe SSDs, which are roughly the size of a stick of gum but offer 5x the speed, essential for high-speed data logging at the edge.

Rich I/O Connectivity: Infinite Links in Finite Space

The value of an Industrial PC Box lies in its ability to talk to the “outside world”—the sensors, actuators, and legacy machines that populate a factory.

Industrial-Specific Interface Configurations (RS-232/GPIO/LAN)

While consumer PCs move toward “USB-C only,” Industrial PCs retain the critical legacy ports required for machine-to-machine (M2M) communication:

- Serial Ports (COM): RS-232/422/485 for controlling PLCs and legacy sensors.

- Isolated DIO/GPIO: Programmable inputs and outputs that are electrically isolated to prevent surges from damaging the mainboard.

- Multiple GbE LAN Ports: Essential for “Dual-homing”—connecting one port to the internal machine network and the other to the corporate ERP/Cloud network for security.

High-Flexibility Modular Expansion (M.2 / Mini PCIe)

Despite the compact size, internal expansion slots allow for “Future-Proofing”:

- Wireless Modules: Adding Wi-Fi 6, 4G LTE, or 5G modules for remote IoT monitoring.

- Capture Cards: Adding specialized video capture cards for medical imaging or high-end machine vision.

| Interface | Typical Application | Strategic Advantage |

| Dual LAN | Network Redundancy | Zero downtime if one cable fails |

| COM Ports | PLC & Sensor Control | Direct hardware-level communication |

| M.2 Key-B/E | 5G / Wi-Fi 6 | Seamless IoT and Cloud integration |

Stability in Harsh Environments: Rugged Design Beyond Commercial Limits

A PC inside a roadside traffic controller or a smelting plant must endure conditions that would destroy a standard laptop in minutes.

The Necessity of Wide Operating Temperatures

Most commercial PCs are rated for 0°C to 35°C. In contrast, an Industrial Embedded PC is engineered for Wide Temperature ranges, typically -20°C to 70°C. This is achieved through industrial-grade capacitors and specialized thermal pads that do not degrade under extreme heat cycling.

Wide Voltage Input and Power Protection

Power on a factory floor is “dirty”—spikes and drops are common.

- 9V ~ 36V DC Input: This flexibility allows the PC to be powered directly by vehicle batteries or industrial power rails without expensive external converters.

- Over-Voltage/Current Protection: Integrated circuitry ensures that even if a nearby motor causes a surge, the PC’s delicate CPU remains unharmed.

Frequently Asked Questions (FAQ)

H3: What is the main difference between an Embedded PC and a standard IPC?

Traditional IPCs (like 4U Rackmounts) are expandable via multiple PCI slots but are bulky. Embedded Box PCs are designed for “Application-Specific” use where space, power efficiency, and environmental protection are prioritized over raw slot count.

How do I choose the right Embedded PC for a cramped space?

Focus on the TDP (Thermal Design Power) of the CPU and the Airflow Gap. Even a fanless PC needs about 2-5cm of clearance to allow hot air to rise away from the cooling fins. Also, ensure the I/O ports are “Front-Facing” if the unit is being tucked into a shallow cabinet.

Can a fanless PC really handle high-end AI or Graphics?

Absolutely. By using optimized Mobile or Embedded CPUs and specialized thermal management, modern fanless PCs can run complex AI models (like YOLO or TensorFlow) 24/7 without thermal throttling.

Beyond Info System: Your Partner in Industrial Embedded Solutions

At Beyond Info System (BIS), we understand that hardware is the foundation of your digital transformation. We specialize in delivering high-reliability Industrial PC Boxes that bridge the gap between “Compact” and “Powerful.”

A Leader in Professionalism and Trust (EEAT)

With years of experience in the embedded sector, Beyond Info System provides not just hardware, but a commitment to quality. Our products undergo rigorous burn-in testing to ensure they perform in the most demanding conditions, backed by long-term supply guarantees.

Featured Product Solutions (Internal Links)

If you are looking for a compact yet powerful computing core, explore our curated selection:

- High-Performance Embedded Box PC Series: Engineered for the next generation of Edge AI and automation.

- UMSM04-NUC / UMSM05 Ultra-Small Series: Our most compact designs, perfect for Kiosk and Smart Retail applications.

- RML-S67 Rugged Military-Grade Series: Built for extreme temperatures and high-vibration environments like rail and heavy industry.

Choosing the right embedded PC is the first step toward a more efficient, reliable, and intelligent operation. Don’t let space constraints limit your technological potential.

Contact Beyond Info System today to consult with our technical experts and find the perfect Industrial PC Box for your specific needs.