What is an Industrial IoT Control Panel?

The Role and Core Functions

An Industrial IoT (IIoT) Control Panel serves as the central interface for managing and monitoring factory equipment and processes. It combines traditional industrial control systems with modern Internet of Things capabilities, enabling real-time communication, data acquisition, and analytics. These control panels bridge the gap between operational technology (OT) and information technology (IT), making them crucial for modern manufacturing ecosystems.

IoT vs. Traditional Control Panels

Unlike traditional panels, IIoT panels support wireless communication, cloud integration, and smart diagnostics. They allow for greater flexibility, scalability, and real-time responsiveness across manufacturing operations. Traditional systems often require manual configuration and lack connectivity, while IIoT panels enable automated control, remote management, and predictive insights that optimize workflows.

Importance in Smart Manufacturing

IIoT control panels are pivotal to smart factory initiatives. They enable machine connectivity, data-driven decision-making, and seamless integration with enterprise systems, forming the backbone of Industry 4.0 architectures. As manufacturers adopt digital transformation, IIoT panels empower them to reduce downtime, improve efficiency, and stay competitive in a rapidly evolving market.

Key Benefits of Using IIoT Control Panels in Manufacturing

Enhanced Connectivity and Data Integration

IIoT control panels facilitate seamless communication between devices using protocols like MODBUS, OPC UA, and MQTT. This allows for centralized data collection and real-time insights. They also support integration with cloud platforms such as Azure and AWS, enabling big data analysis, machine learning, and advanced reporting.

Real-Time Monitoring and Predictive Maintenance

With built-in sensors and edge computing capabilities, IIoT panels support real-time monitoring, alerting operators of anomalies or potential breakdowns before they occur. Predictive maintenance reduces unplanned downtime and extends the lifespan of critical machinery.

Reduced Maintenance and Labor Costs

Automated alerts, remote diagnostics, and self-check functions minimize manual intervention, reducing operational costs and downtime. Maintenance teams can act proactively rather than reactively, streamlining operations and optimizing resource allocation.

Top 10 Application Scenarios for IIoT Control Panels

1. Smart Production Line Monitoring

IIoT control panels provide real-time dashboards for operators, enabling precise control over machine status, output, and performance across automated production lines. This results in increased throughput and reduced human error.

2. Energy and Asset Management

They allow for detailed tracking of energy consumption and equipment utilization, helping manufacturers reduce waste and improve efficiency. Through energy analytics, companies can identify inefficiencies and implement energy-saving strategies.

3. Factory Safety and Environmental Control

Integrated with environmental sensors, control panels monitor temperature, humidity, air quality, and hazardous gas levels to maintain safe working conditions. Alerts and automatic shutdowns can be configured to respond to dangerous thresholds.

4. Remote Maintenance and Troubleshooting

IIoT-enabled panels support remote access, allowing technicians to diagnose and update systems without being physically present, saving time and travel costs. This is especially beneficial for facilities in remote or hazardous locations.

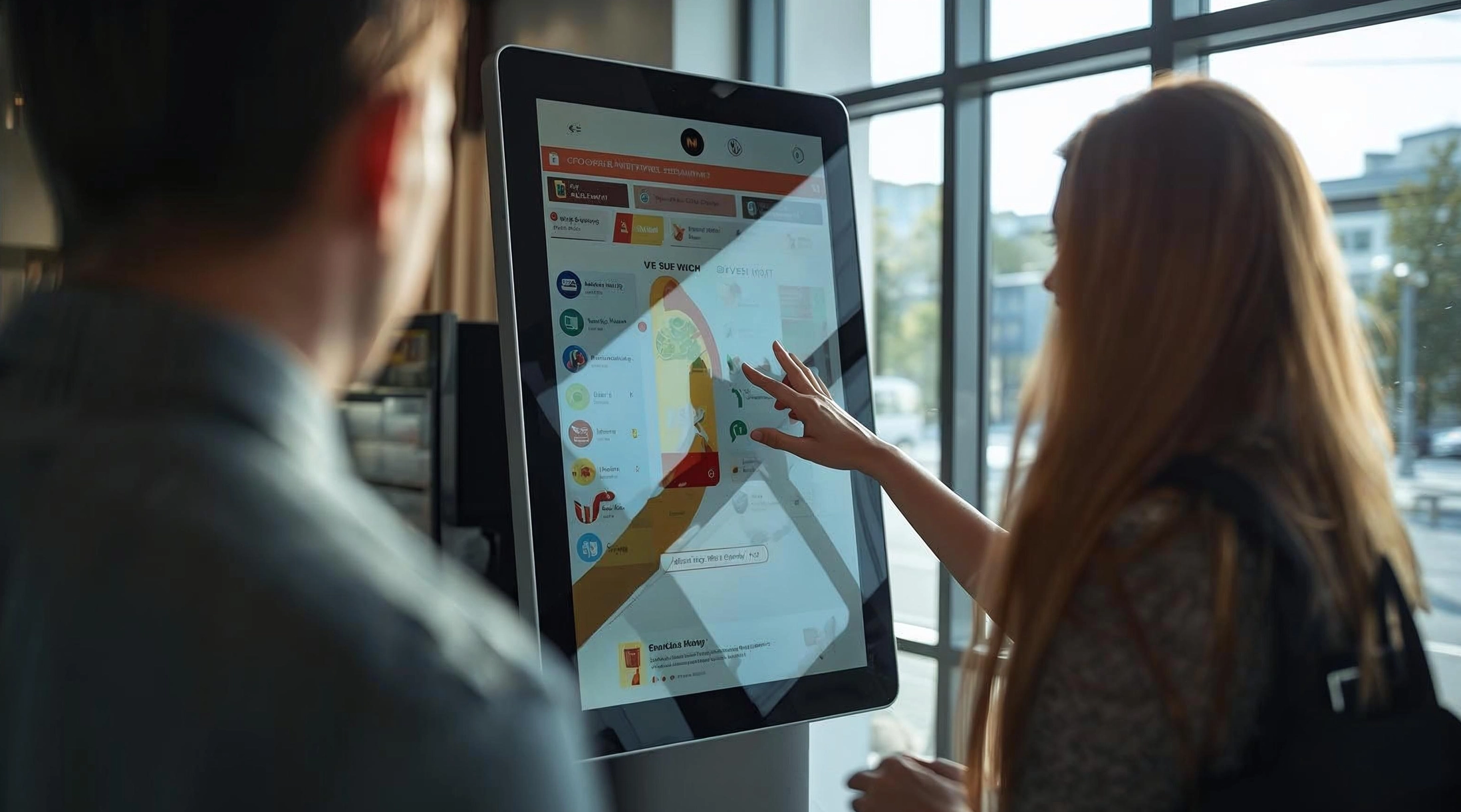

5. HMI and Data Visualization Interfaces

With user-friendly Human-Machine Interfaces (HMI), operators can visualize complex data, streamline workflows, and perform touch-based operations intuitively. Custom dashboards can be configured to display KPIs, alarms, and historical trends.

6. Digital Twin Implementation

By syncing real-time machine data with digital models, manufacturers can simulate, predict, and optimize factory operations virtually. Digital twins enhance design processes, risk assessment, and operational planning.

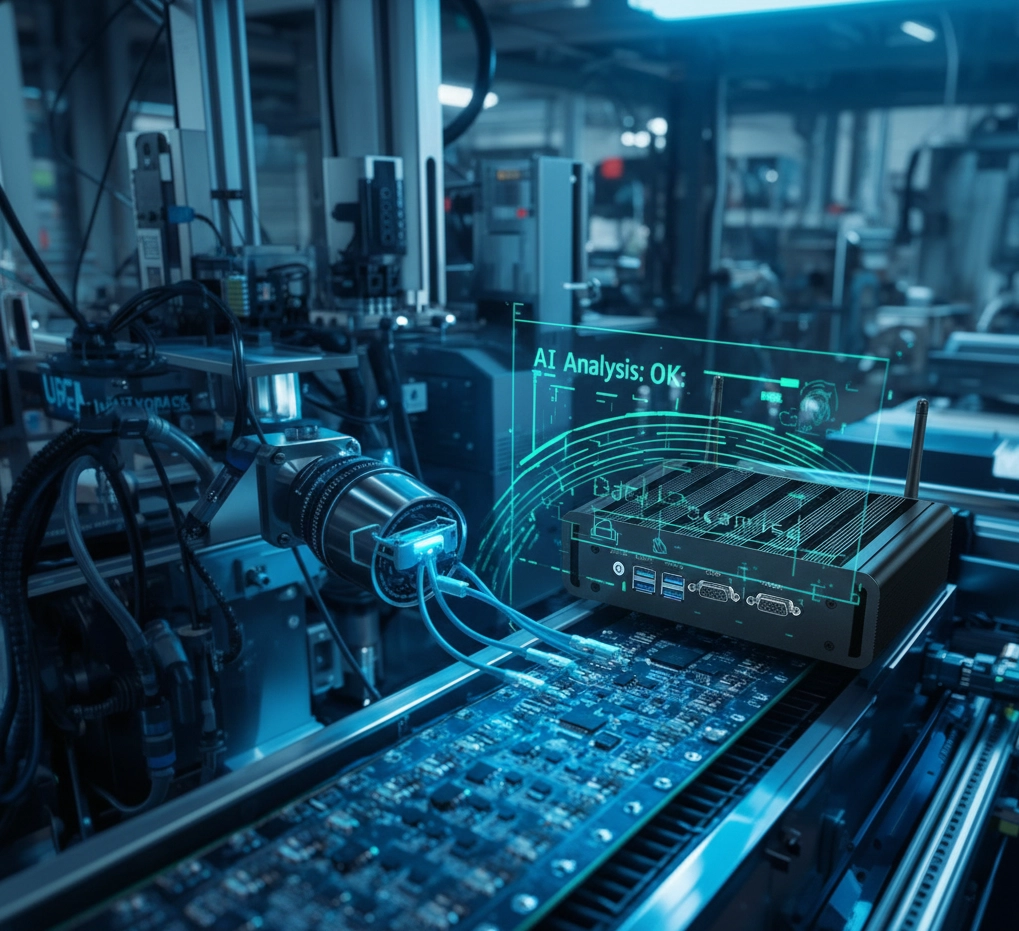

7. Edge Computing for Local Decision-Making

IIoT panels with embedded edge computing analyze data on-site, enabling faster decision-making and reducing reliance on cloud infrastructure. This is critical for latency-sensitive applications and real-time control.

8. Integration with MES/ERP Systems

Seamless data exchange with Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) improves coordination across departments. From inventory updates to production scheduling, IIoT panels act as a key link in the information chain.

9. Cross-Factory Equipment Management

IIoT control panels enable centralized control over distributed facilities, allowing management to monitor and configure equipment remotely. This supports global manufacturing strategies and ensures standardization.

10. Process Traceability and Quality Assurance

With real-time tracking and historical data logging, manufacturers can trace production issues, meet compliance standards, and improve quality control. This is vital in industries like pharmaceuticals, food processing, and electronics.

Considerations Before Implementing IIoT Control Panels

Hardware Specifications

Key factors include CPU performance, memory capacity, ruggedness, and support for industrial I/O interfaces. Look for IP65-rated enclosures for dust and water protection, along with fanless designs that minimize maintenance.

Communication Protocol Support

Ensure compatibility with major industrial protocols such as MODBUS, OPC UA, MQTT, and Ethernet/IP to guarantee seamless device integration. This ensures future-proofing and adaptability to evolving automation systems.

Environmental Suitability

Consider deployment conditions such as temperature extremes, vibration, and moisture. Select devices built to military or industrial-grade standards for harsh environments, including wide temperature ranges and anti-corrosion coatings.

Frequently Asked Questions (FAQ)

Common Implementation Questions

What is the difference between an IIoT control panel and a PLC?

While both manage industrial automation tasks, IIoT panels offer enhanced connectivity, data processing, and user interface capabilities compared to traditional PLCs. IIoT panels can complement or replace PLCs depending on the application.

Can IIoT panels integrate with existing SCADA systems?

Yes, modern control panels are designed for easy integration with SCADA platforms, supporting both legacy and modern communication protocols. This ensures minimal disruption during upgrades.

Are IIoT panels reliable in extreme environments?

Industrial-grade panels are built for rugged use, featuring high-temperature tolerance, shock resistance, and waterproof enclosures. Many models are certified for use in outdoor or hazardous zones.

Benefits and ROI

Deployment cuts downtime, lifts OEE, trims maintenance costs, and improves yields via visualization and predictions. Keywords: OEE gains, cost reductions. Typical ROI occurs within 12-18 months.